Stainless Steel 316 Pipe

Get Professional Help

98400 36235

Stainless steel 316 pipe belongs to an austenitic grade. The Stainless Steel 316 Pipe is designed with a superior content of 16-18% chromium, 10-12% nickel with 2-3% molybdenum. The outstanding content embedded in the SS 316 Pipe gives them enhanced corrosion and oxidation resistance properties in an array of environments. The versatile Marine Stainless Steel Pipe has good tolerance to reducing acids, crevice corrosion, and pitting by acids in marine systems. The robust 316 Stainless Steel Tube exhibits intermittent service temperatures of between 870 degrees C to 925 degrees C. The grade of Stainless Steel 316 Tube can work well in continuous temperatures between 425-860 degrees C. These tubes can be readily welded in place following standard welding procedures. 316 Stainless Steel Pipe is designed with excellent mechanical properties. These pipes have a minimum tensile strength of 515mpa with a minimum yield strength of 205mpa. This 316 Stainless Steel Pipe can be readily elongated by 40% while showcasing a density of 8.0 kg/m3. They have a hardness of 217 max Brinell. SS 316 Pipe cannot be hardened by standard thermal treatment. These pipes are annealed at temperatures between 1010 to 1120 degrees C, followed by rapid cooling.

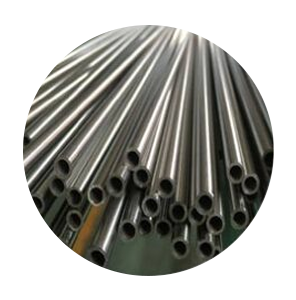

An SS 316 Seamless Pipe is designed by passing hot steel billets through an extruded metal, allowing it to be shaped in precise dimensions. An SS 316 Seamless Pipe grade doesn’t possess any welds or seams and exhibits superior strength and load-bearing capacity. On the contrary, an ASTM A312 TP316 Welded Pipe is designed with welds, which give it a lower weight-holding capacity than seamless pipes; however, they are cheaper to produce and purchase. ASA312 TP316 ERW Pipe is produced by passing electric current to longitudinally seam weld the piping module in place. A 316 Seamless Tubing made and shipped from India is comparatively cheaper than that from the USA or other European countries.

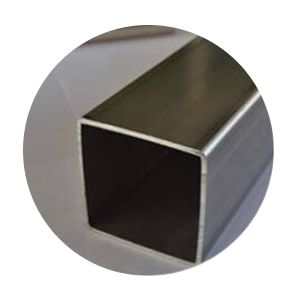

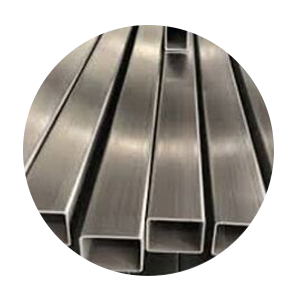

The A312 GR TP316 Square Pipe is designed with a square cross-sectional area. These pipes are equal on all sides. Similar to this is the ASTM A213 TP316 Rectangular Pipe, which has slightly higher strength and load-bearing capacity than a square pipe.

316 Stainless Steel Pipe Specifications

| Dimensions | ASME, ASTM and API |

|---|---|

| Specifications | ASME SA 312 ASTM A 312 / ASME SA 358ASTM A 358 |

| SS 316 Pipes | 1/2 inch NB – 16 inchNB |

| EFW 316 Pipes | 6 inch NB – 100 inchNB |

| ERW 316 Pipes | 1/2 inch NB – 24 inch NB |

| Size | 1/8 inchNB TO 30 inch NB IN |

| Schedule | SCH30, SCH20, SCH40, XS, SCH160, SCH80, SCH60, SCH120,SCH80, SCH140, XXS |

| Specialized in | Large Dia Size |

| Form | Square, Round, Hydraulic,Rectangular Etc |

| End | Beveled End, Plain End, Treaded |

| Type | ERW / Seamless / Welded / LSAW /Fabricated Pipes |

| Length | Single Double & Cut Length. |

Types Of Stainless Steel 316 Pipe

316 Stainless Steel Square Tubing

Schedule 40 316 Stainless Steel Pipe

Schedule 10 316 Stainless Steel Pipes

A269 Tp316

316 Stainless Steel Rectangular Tubing

25mm 316 Stainless Steel Tube

1 Inch 316 Stainless Steel Tubing

316 Stainless Steel Tubing Polished

Ss 316 Seamless Pipes

316 Polished Stainless Tubing

316 Stainless Square Tube

Polished 316 Stainless Steel Tube

SS 316 Seamless Pipe Weight Chart

| Sizes (in inches) | Sizes (in mm) | OD (in inches) | OD (in mm) | 316 SS Pipes wall thichness (in inches) | 316 SS Pipes wall thichness (in mm) | Weight (in lbs/ft) | Weight (in kg/m) |

|---|---|---|---|---|---|---|---|

| 0.54 | 13.716 | 0.088 | 2.2352 | 0.364 | 9.2456 | 0.425 | 0.6324697 |

| 0.54 | 13.716 | 0.119 | 3.0226 | 0.302 | 7.6708 | 0.5353 | 0.7966141892 |

| 0.84 | 21.336 | 0.109 | 2.7688 | 0.622 | 15.7988 | 0.8513 | 1.2668740132 |

| 0.84 | 21.336 | 0.147 | 3.7338 | 0.546 | 13.8684 | 1.088 | 1.619122432 |

| 1.05 | 26.67 | 0.113 | 2.8702 | 0.824 | 20.9296 | 1.131 | 1.683113484 |

| 1.05 | 26.67 | 0.154 | 3.9116 | 0.742 | 18.8468 | 1.474 | 2.193553736 |

| 1.315 | 33.401 | 0.133 | 3.3782 | 1.049 | 26.6446 | 1.68 | 2.50011552 |

| 1.315 | 33.401 | 0.179 | 4.5466 | 0.957 | 24.3078 | 2.173 | 3.233780372 |

| 1.66 | 42.164 | 0.140 | 3.556 | 1.380 | 35.052 | 2.221 | 3.305212244 |

| 1.9 | 48.26 | 0.145 | 3.683 | 1.610 | 40.894 | 2.734 | 4.068640376 |

| 1.9 | 48.26 | 0.200 | 5.08 | 1.500 | 38.1 | 3.654 | 5.437751256 |

| 2.375 | 60.325 | 0.154 | 3.9116 | 2.067 | 52.5018 | 3.654 | 5.437751256 |

| 2.375 | 60.325 | 0.218 | 5.5372 | 1.939 | 49.2506 | 5.024 | 7.476535936 |

| 2.875 | 73.025 | 0.203 | 5.1562 | 2.469 | 62.7126 | 5.795 | 8.62391038 |

| 2.875 | 73.025 | 0.276 | 7.0104 | 2.323 | 59.0042 | 7.664 | 11.405288896 |

| 3 1/2 | 88.90 | 0.216 | 5.4864 | 3.068 | 77.9272 | 7.002 | 10.420124328 |

| 3 1/2 | 88.90 | 0.300 | 7.62 | 2.900 | 73.66 | 10.257 | 15.264098148 |

| 8.625 | 219.075 | 0.322 | 8.1788 | 7.981 | 202.7174 | 28.564 | 42.507916496 |