API 5L Grade B Pipe

Get Professional Help

98400 36235

What Is API 5L Gr B Pipe?

API 5L Gr B is a grade of the American Petroleum Institute. The API 5L Grade B Pipe covers seamless and welded pipe types. These pipes are designed for transmission lines in oil, petroleum, and natural gas. API 5L Gr B Pipe is designed with an outstanding chemical composition of carbon, manganese, phosphorous, sulfur, silicon, copper, nickel, chromium, and molybdenum. API 5L Gr B material showcases superior corrosion and oxidation resistance properties that are essential in the volatile system they are designed to work in. The grade covers PSL1 and PSL2 for sour and offshore service systems. The API 5L Grade B PSL2 High Yield Pipe showcases exceptional strength, chemical properties, and mechanical strength allowing it to be used in stress-induced setups. The API 5L Grade B material showcases a minimum tensile strength of 415mpa with a minimum yield strength of 240mpa in the system.

How Do I Know If My API 5L Grade B Pipe Is ERW Or Seamless?

The API 5L grade pipes are designed in different configurations that can be distinguished on certain basic features. API 5L Grade B ERW Pipe is a cold-formed strip that is rounded by passing it through a series of rollers to give it a longitudinal seam. The two edges of the API 5L Grade B ERW Pipe are welded in place with a high-frequency current. These pipes show the presence of seams or welds on their surface. An API 5L Grade B Seamless Pipe is designed without any seams or welds as it is produced through an extrusion process. This is why seamless types of pipes are preferred in applications requiring high-strength and load-bearing capacity over API 5L Grade B Welded Pipe.

What Is API 5L Gr B Nace Pipe?

Nace pipe is a component that is designed with anti-corrosion material in the pipeline industry. The API 5L Gr B Nace Pipe is utilized in transporting H2S-containing material that is seen in oil and gas transportation. The API 5L Grb HIC Pipeline protects the piping types against sulfide stress cracking, stress corrosion cracking, and other corrosive media as it transports high-pressure fluids and gases.

API 5L Grade B Pipe Specification

| Size Range | 1/2 to 36 inch NB |

|---|---|

| Schedule Thickness Range | SCH 40, 80, 160, XS, XXS, All Schedules |

| Applications | Power Generation, Oil Refineries, Petrochemicals, General Engineering Purposes, Pressure Vessels, Sugar, Boiler Equipments |

| Pipes Type | Seamless, ERW, Welded, Fabricated CDW |

| Pipes & Tube Form | Round, Square, Rectangular, Coiled, "U" Shape, Pan Cake Coils, Hydraulic Tubes |

| Marking | Supplier / Manufacturer's Name or Custom Logo - on request |

| Heat Number | |

| Manufacturing Method (Welded / Seamless) | |

| Nominal Pipes Sizes | |

| Specification | |

| Grade | |

| Pipes Schedule or Wall Thickness | |

| Length: | Single, Double Random & Length, Custom Size - 12 M lengths |

| End | Beveled End, Plain End, Treaded |

| End Protection: | Plastic Caps |

| End Connections for Line Pipes | Plain, Bevel, Screwed, Threaded |

| Outside Coating | Black Painting, Anti-Corrosion Oil, Galvanised Finish |

API 5L Grade B Erw Pipe Specification

| Supply Range | Diameters for API 5L welded (ERW, SAW) line pipe 1/2" to 60" |

|---|---|

| Grade | API 5L Grade B, X42, X46, X52 X56, X60, X65, X70, X80 |

| Manufacturing types | ERW, LSAW, SSAW |

| Range of Thickness | SCH10 to SCH160 |

| Ends Type | Beveled ends, Plain ends |

| Range of length | 20FT, 40FT or customized |

| Protection | Caps in plastic or iron available |

| Surface appearances | Natural Varnished, Black painting, 3PE, FBE, |

API 5L Gr B Material Types

API 5L Grade B Pipe

API5LB Pipes

API 5L Grade B SAW Pipes

API 5L Grade B LSAW Pipes

API 5L Grade B SSAW Pipes

API 5L Grade B HSAW Pipes

API 5L Grade B Line Pipe

Schedule 40 API 5L Grade B Pipe

Sch 80 API 5L Grade B Pipe

L245 Pipe

ISO 3183 Seamless Pipes

API 5L Gr B Pipe

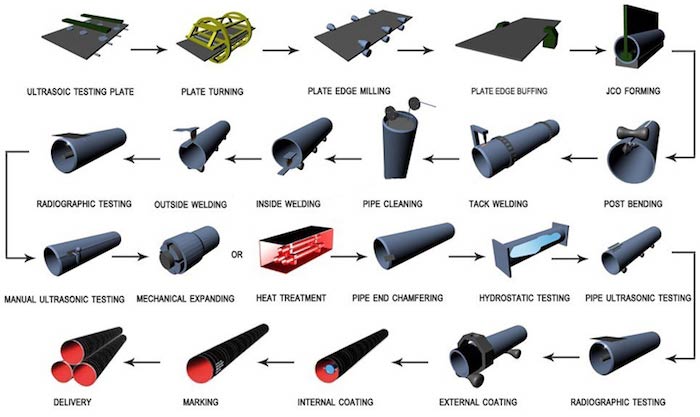

API 5L Grade B Lsaw Pipe Manufacturing Process

API 5L Grade B Schedule 40 Pipes Length

Table 12— Tolerances for random length pipe

| Random length designation m(ft) |

Minimum length m(ft) |

Minimum average length for each order item m(ft) |

Maximum lenght m(ft) |

|---|---|---|---|

| Threaded-and-coupled pipe | |||

|

6 (20) |

4,88 (16.0) |

5,33 (17.5) |

6,86 (22.5) |

|

9 (30) |

4,11 (13.5) |

8,00 (26.2) |

10,29 (33.8) |

|

12 (40) |

6,71 (22.0) |

10,67 (35.0) |

13,72 (45.0) |

| Plain-end pipe | |||

|

6 (20) |

2,74 (9.0) |

5,33 (17.5) |

6,86 (22.5) |

|

9 (30) |

4,11 (13.5) |

8,00 (26.2) |

10,29 (33.8) |

|

12 (40) |

4,27 (14.0) |

10,67 (35.0) |

13,72 (45.0) |

|

15 (50) |

5,33 (17.5) |

13,35 (43.8) |

16,76 (55.0) |

|

18 (60) |

6,40 (21.0) |

16,00 (52.5) |

19,81 (65.0) |

|

24 (80) |

8,53 (28.0) |

21,34 (70.0) |

25,91 (85.0) |