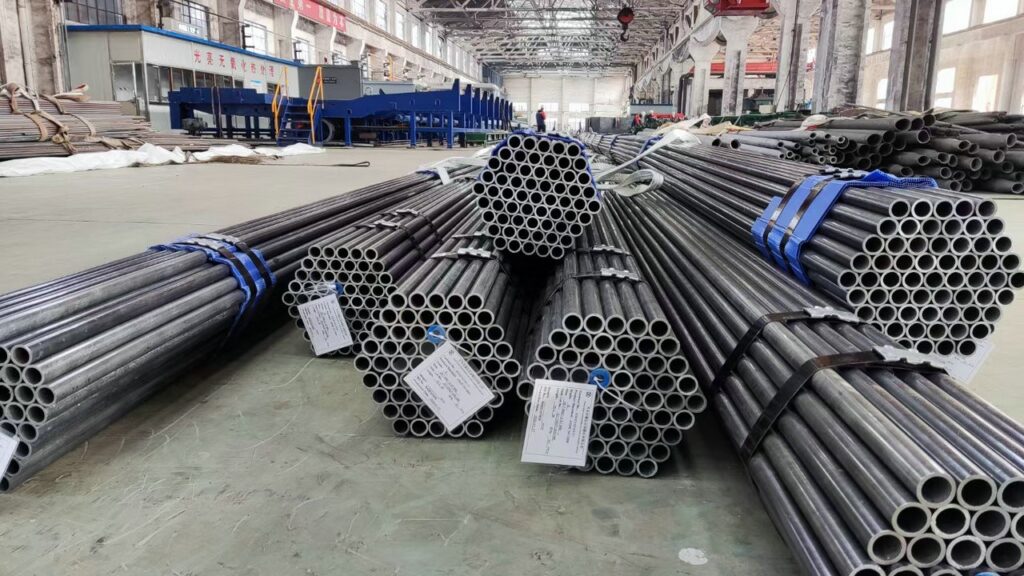

Carbon Steel Pipe

Get Professional Help

98400 36235

What Is Carbon Steel Pipe?

Carbon steel piping components are designed with a superior carbon content spanning between 0.5 to 2.1 percent in weight. A Carbon Steel Pipe is constituted with different alloys that give it good corrosion and oxidation resistance properties in the systems. PTFE-lined carbon steel pipe has a low melting point and outstanding durability in severe applications. They can operate in high pressures and temperatures up to 230 degrees C. FBE-lined carbon steel pipes are made up of two substrates that protect them against corrosive media over long periods. The versatile galvanized carbon steel pipe is produced by dipping the module in zinc, thereby improving the resistance and tolerance of the pipe grade.

Carbon Steel Pipe Specification

| Available Materials | ST35.8, Q235 X42 St37.2, St35.4/8, STPT49 G42, STS42, STP STB42, St52.4STP to A53B, X80, G38, A106B, ST37.0, 5LB, API St45, STPT42, St42, St52, material supplier in India |

|---|---|

| Common Standard | ASTM A53, A106, API 5L ASME 836.10 DIN1626, DIN1629, DIN17175, JIS G3454, JIS G3456, JIS G3461, EN10216-1, EN 10208 |

| Standard Size | 1/2 Inch Nominal Bore to 36 Inch Nominal Bore (LSAW, SSAW, HSAW) / (DN15 to DN900) |

| Dimensions | ASME/ ANSI B36.10 / 19 |

| Codes and Standards | ASME, ANSI, ASTM, SAE, API, BS, AWWA,AGA, ISO, DIN |

| Supplier of Carbon Steel Pipes offer various shapes | Round, Oval, Triangle, Semi-Round Semi-oval, Rhomboid, Square, Rectangle, Hollow, Elliptical Hollow, Semi-Rhomboid, |

| Producing techniques | Seamless / ERW / Welded / Fabricated/CD/EFW |

| Wall Thk | 3-12m milimeter |

| Pipes schedules | SCH 80S, SCH 5, SCH 40, SCH10, SCH 80, SCH XXS, SCH 160, SCH XS Supplier |

| Available Shapes | Half Round Round, Rectangular Square or Custom shape CS Pipes supplier and manufacturer |

| Marking | Nominal Pipes Sizes Specification Manufacturing Method (Welded/Seamless) Grade Pipes Schedule or Wall Thickness Supplier / Manufacturer’s Name or Custom Logo – on request Heat Number |

| Pipes End | Beveled End, Plain End, Treaded |

| Length | 3 to Maximum 18 M or custom Size |

| Surface Finishe | Black painting, Epoxy, FBE, Varnish, 3PE, etc. |

| Test Certificates provided by suppliers | EN 10204 3.1 B |

| Material Test Certificate (MTC) provided by Carbon Steel Pipe Supplier | ISO 14001:2015, PED, ISO 9001:2005, Ultrasonic Testing (UT), NDE, EIL, Radiographic Testing (RT), IBR, |

Types Of Carbon Steel Pipe

Carbon Steel Pipe

Carbon Steel Tube

Carbon Steel Seamless Pipe

Carbon Steel Erw Pipe

Carbon Steel Welded Pipe

Sch 40 Carbon Steel Pipe

Black Carbon Steel Pipe

Carbon Seamless Steel Pipe

Galvanized Carbon Steel Pipe

Low Carbon Steel Pipe

Large Diameter Carbon Steel Pipe

Coated Carbon Steel Pipe

Cs Seamless Pipe

Epoxy Lined Carbon Steel Pipe

Epoxy Coated Carbon Steel Pipe

Carbon Steel Tubing Pressure Ratings

| Nominal Tube O.D. | Nominal Tube wall thickness | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.028 | 0.035 | 0.049 | 0.065 | 0.083 | 0.093 | 0.109 | 0.120 | 0.134 | 0.148 | 0.156 | 0.188 | ||

| inch | mm | 0.71mm | 0.89mm | 1.24mm | 1.65mm | 2.11mm | 2.41mm | 2.77mm | 3.05mm | 3.40mm | 3.76mm | 3.96mm | 4.78mm |

| Reference Working Pressures at 4:1 Design Factor(psi/MPa) | |||||||||||||

| 0.125 | 6650 | 8450 | |||||||||||

| 3.18 | 46.0 | 58.5 | |||||||||||

| 0.188 | 4250 | 5450 | |||||||||||

| 4.77 | 29.5 | 37.5 | |||||||||||

| 0.250 | 3100 | 3950 | 5750 | 7800 | |||||||||

| 6.35 | 21.5 | 27.0 | 39.5 | 54.0 | |||||||||

| 0.312 | 2450 | 3100 | 4500 | 6150 | |||||||||

| 7.92 | 16.8 | 21.5 | 31.0 | 42.5 | |||||||||

| 0.375 | 2000 | 2550 | 3650 | 5000 | 6550 | 7600 | |||||||

| 9.53 | 13.8 | 17.6 | 25.0 | 34.5 | 45.0 | 52.5 | |||||||

| 0.500 | 1850 | 2700 | 3650 | 4800 | 5550 | 6450 | 7200 | ||||||

| 12.70 | 12.8 | 18.6 | 25.0 | 33.0 | 38.5 | 44.5 | 49.5 | ||||||

| 0.625 | 1500 | 2100 | 2850 | 3750 | 4350 | 5050 | 5600 | ||||||

| 15.88 | 10.4 | 14.5 | 19.6 | 26.0 | 30.0 | 35.0 | 38.5 | ||||||

| 0.750 | 1200 | 1750 | 2350 | 3050 | 3550 | 4150 | 4600 | ||||||

| 19.05 | 8.3 | 12.0 | 16.2 | 21.0 | 24.5 | 28.5 | 31.5 | ||||||

| 0.875 | 1050 | 1500 | 2000 | 2600 | 3000 | 3500 | 3900 | ||||||

| 22.23 | 7.2 | 10.4 | 13.8 | 18.0 | 20.5 | 24.0 | 27.0 | ||||||

| 1.000 | 900 | 1300 | 1750 | 2250 | 2600 | 3000 | 3350 | 3800 | 4200 | ||||

| 25.40 | 6.2 | 9.0 | 12.0 | 15.5 | 18.0 | 20.5 | 23.0 | 26.0 | 29.0 | ||||

| 1.125 | 1150 | 1550 | 2000 | 2300 | 2650 | 2950 | 3300 | 3700 | |||||

| 28.58 | 7.9 | 10.6 | 13.8 | 15.8 | 18.2 | 20.5 | 23.0 | 25.5 | |||||

| 1.250 | 1000 | 1350 | 1750 | 2050 | 2350 | 2650 | 2950 | 3300 | 3500 | 4300 | |||

| 31.75 | 6.9 | 9.3 | 12.0 | 14.2 | 16.2 | 18.2 | 20.5 | 23.0 | 24.0 | 29.5 | |||

| 1.500 | 1150 | 1450 | 1700 | 1950 | 2150 | 2450 | 2700 | 2850 | 3500 | ||||

| 38.10 | 7.9 | 10.0 | 11.8 | 13.5 | 14.8 | 16.8 | 18.6 | 19.6 | 24.0 | ||||

| 1.750 | 950 | 1250 | 1450 | 1650 | 1850 | 2050 | 2300 | 2400 | 2950 | ||||

| 44.45 | 6.6 | 8.6 | 10.0 | 11.4 | 12.8 | 14.2 | 15.8 | 16.6 | 20.5 | ||||

| 2.000 | 850 | 1100 | 1250 | 1450 | 1600 | 1800 | 2000 | 2100 | 2550 | ||||

| 50.80 | 5.9 | 7.6 | 8.6 | 10.0 | 11.0 | 12.4 | 13.8 | 14.5 | 17.6 | ||||